Process

Design and Engineering for Injection Molding

Capable Plastic works with customer on part design at the early phase of the project. We believe our knowledge and experience in plastic products will assist our customers to develop high quality, cost effective product. Flow simulation will also be used for the design. A clear understanding of the customer’s objectives combined with our Advanced Product Quality Planning (APQP) procedures, knowledge, and experience enable our company to provide services beyond satisfaction.

Capable Plastic works with customer on part design at the early phase of the project. We believe our knowledge and experience in plastic products will assist our customers to develop high quality, cost effective product. Flow simulation will also be used for the design. A clear understanding of the customer’s objectives combined with our Advanced Product Quality Planning (APQP) procedures, knowledge, and experience enable our company to provide services beyond satisfaction.

Rapid Prototyping

Capable Plastic in-house rapid prototype provides service with fast turnaround time. By using Fused Deposition Modeling (FDM) technology, it allows affordability and durability by printing concepts models with production grade material. Small models can be ready in hours.

Capable Plastic in-house rapid prototype provides service with fast turnaround time. By using Fused Deposition Modeling (FDM) technology, it allows affordability and durability by printing concepts models with production grade material. Small models can be ready in hours.

Mould Making

Our In-house and offshore tool room both build moulds to the exact specifications for special requirements of your application. Capable Plastic is attuned to maintaining your moulds for a long-life, trouble-free operation, which assures you of the maximum tool life for your investment.

Our In-house and offshore tool room both build moulds to the exact specifications for special requirements of your application. Capable Plastic is attuned to maintaining your moulds for a long-life, trouble-free operation, which assures you of the maximum tool life for your investment.

Injection Molding

Our head office is strategically located in Concord, Ontario to work closely with our customer to provide fast turnaround support. As a custom injection molder of thermoplastic products, our processing department has a wide machine capacity ranging from 55 to 350 metric tons clamp force. Our production room is equipped with all the necessary auxiliary equipment such as gas assist injection molding. We believe our commitment to an efficient and fully automated production facility will result in high quality parts produced at competitive price.

Our head office is strategically located in Concord, Ontario to work closely with our customer to provide fast turnaround support. As a custom injection molder of thermoplastic products, our processing department has a wide machine capacity ranging from 55 to 350 metric tons clamp force. Our production room is equipped with all the necessary auxiliary equipment such as gas assist injection molding. We believe our commitment to an efficient and fully automated production facility will result in high quality parts produced at competitive price.

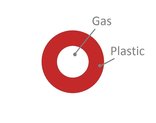

Gas Assist Injection Molding

Capable Plastics has employed gas assist molding technology for plastic injection molding to reduce cycle time and material cost. It also improves both part quality and design freedom.

Capable Plastics has employed gas assist molding technology for plastic injection molding to reduce cycle time and material cost. It also improves both part quality and design freedom.

Capable Plastic Injection & Mould Ltd.

Copyright 2022

all rights reserved